FFCP - Extruder Not Extruding After Raft

Posted: Wed Jun 05, 2019 1:28 pm

Hello all. I bought a Flashforge Creator Pro a couple of months ago, along with the discounted Simplify3D license. I printed a few Thingiverse bits and bobs, which came out fine for the most part, and the FFCP's included dual extrusion test part also printed well. I am using Flashforge PLA filament.

However, I have been finding that the extrusion has been getting progressively "weaker" during prints, indicated by thin infill and top/bottom skins. Playing with settings in S3D has not helped, and now the thing has completely failed to extrude when trying to print my actual parts. The raft seems to print fine every single time, or at least it seems to (the infill pattern's tracks seem like they are maybe not as wide as they should be), but as soon as it finishes the raft and starts on the actual part, it will weakly extrude part of the bottom skin for maybe 30 seconds, and then nothing at all.

For reference, I am new to 3D printing, but not precision mechanical systems (engine & cylinder head rebuilding, machine tools, etc). So as far as I can tell it is not the obvious stuff:

- Bed is leveled, and verified with a dial indicator on the X rails

- Extruder is not jammed, and the feed gear is clean

- PLA material with 230°C hot end, measuring 1.72~1.76mm in diameter

- 60°C bed temperature

Before I ever made a single print on the FFCP, I installed MicroSwiss all metal hot ends since that sounded like a very worthwhile upgrade. It is all installed per the instructions, with the sleeves tight against the nozzles and set to the proper height relative to the cooling bar. Initial prints came out good.

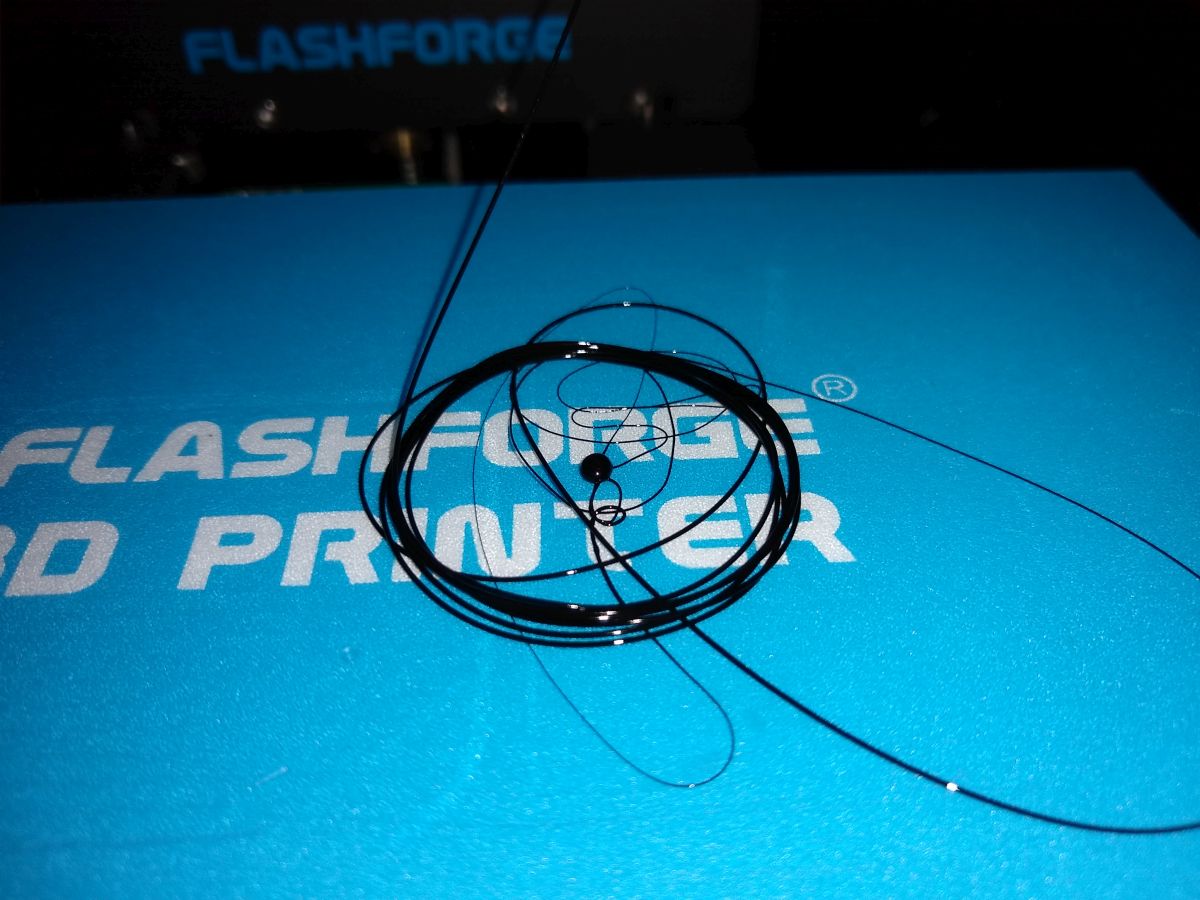

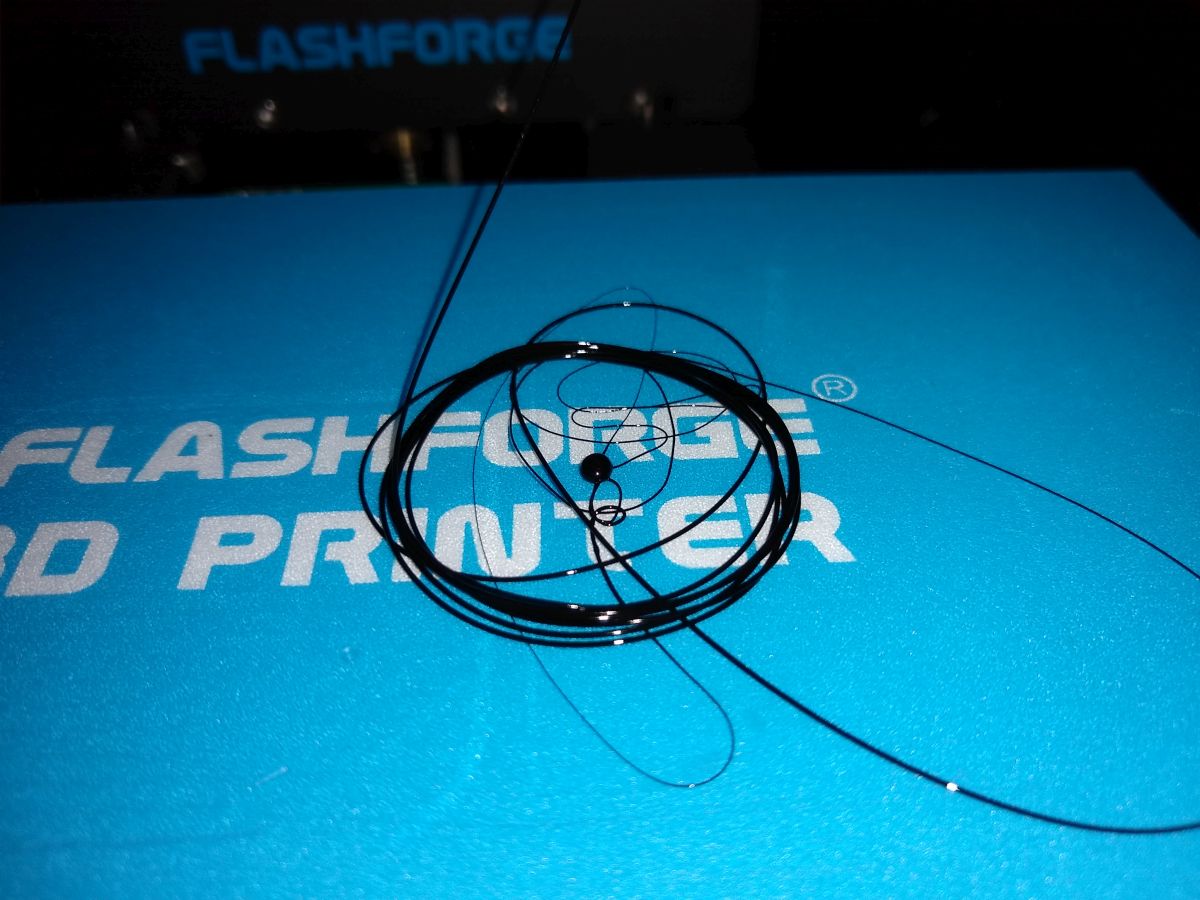

Now, all prints fail per my description above. If I cancel the print or wait for it to finish (despite not actually extruding anything other than the raft), I can go into Utilities and tell it to load filament, and it will start spitting it out just fine, so it is not a jamming issue. But, and I suspect that this is related, the material it spits out has some odd behavior. I get a big blob, then thin stringy extrusion for a few inches, which then gradually gets wider and wider until it looks like it is the proper 0.4mm diameter. See the photos below.

So, are there ways to test the extrusion "calibration" to see if it is an issue with the feed rate being too low, and then corresponding settings in S3D to compensate for this? Or does it sound like there is something wrong in the physical setup of the extruders? Thanks!

However, I have been finding that the extrusion has been getting progressively "weaker" during prints, indicated by thin infill and top/bottom skins. Playing with settings in S3D has not helped, and now the thing has completely failed to extrude when trying to print my actual parts. The raft seems to print fine every single time, or at least it seems to (the infill pattern's tracks seem like they are maybe not as wide as they should be), but as soon as it finishes the raft and starts on the actual part, it will weakly extrude part of the bottom skin for maybe 30 seconds, and then nothing at all.

For reference, I am new to 3D printing, but not precision mechanical systems (engine & cylinder head rebuilding, machine tools, etc). So as far as I can tell it is not the obvious stuff:

- Bed is leveled, and verified with a dial indicator on the X rails

- Extruder is not jammed, and the feed gear is clean

- PLA material with 230°C hot end, measuring 1.72~1.76mm in diameter

- 60°C bed temperature

Before I ever made a single print on the FFCP, I installed MicroSwiss all metal hot ends since that sounded like a very worthwhile upgrade. It is all installed per the instructions, with the sleeves tight against the nozzles and set to the proper height relative to the cooling bar. Initial prints came out good.

Now, all prints fail per my description above. If I cancel the print or wait for it to finish (despite not actually extruding anything other than the raft), I can go into Utilities and tell it to load filament, and it will start spitting it out just fine, so it is not a jamming issue. But, and I suspect that this is related, the material it spits out has some odd behavior. I get a big blob, then thin stringy extrusion for a few inches, which then gradually gets wider and wider until it looks like it is the proper 0.4mm diameter. See the photos below.

So, are there ways to test the extrusion "calibration" to see if it is an issue with the feed rate being too low, and then corresponding settings in S3D to compensate for this? Or does it sound like there is something wrong in the physical setup of the extruders? Thanks!